Automation of repetitive pallet handling

Toyota offers a range of automated warehouse forklifts, Autopilots, for different types of material handling:

Automated low-lifter truck LAE250

- up to 2.5 tonne load capacity

- optional with 2.4 m fork length

- max speed of 2.2m/s

- long-distance pallet transport

Automated stacker truck SAE160

- up to 1.6 tonne load capacity

- up to 4.7 m lift height

- max. speed of 2.2m/s

- medium-level storage

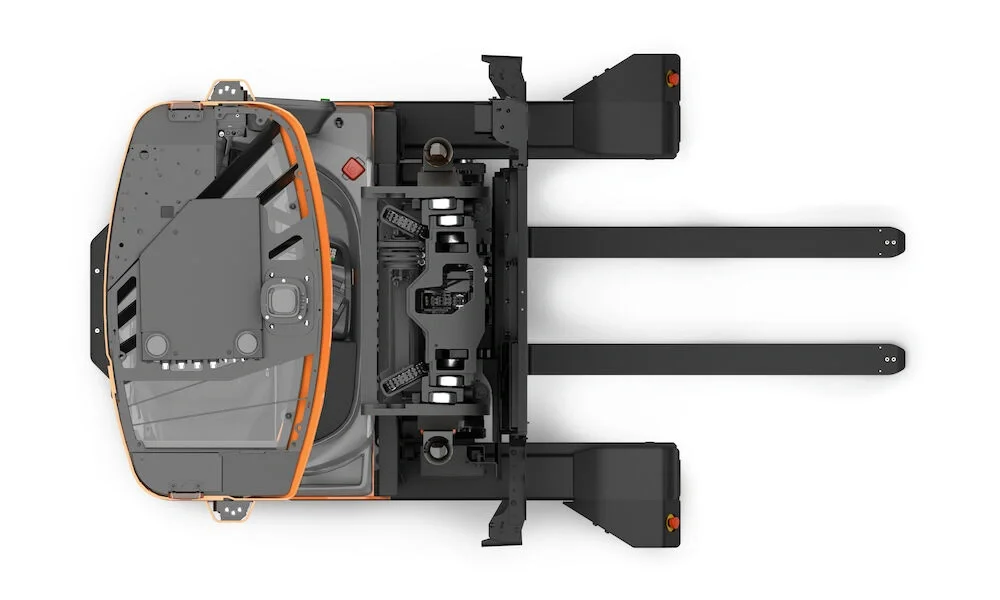

Automated counterbalanced truck OAE120CB

- up to 1.2 tonne load capacity

- up to 4.15 m lift height

- max. speed of 2.2m/s

- variety of load carriers

- medium-level storage

Automated reach trucks RAE160-250

- up to 2.5 tonne load capacity

- up to 11 m lift height

- max. speed of 2.0m/s

- high-level storage

The Autopilots in action

Automated warehouse trucks guarantee fast and safe horizontal transport of pallets, particularly suited to handle repetitive long-distance transport. This way your warehouse staff can handle more value-added and complex tasks instead, while the Autopilot range from Toyota guarantees a smooth and lean workflow. The Autopilots can be equipped with Lithium-Ion batteries for auto charging, meaning the trucks can charge in between tasks without the need of personnel or charging rooms, making it fully automated.

Safe and accurate pallet handling

Autopilots are programmed to complete all tasks safely, and to work alongside manual operators. The built-in safety scanners and obstacle detection units prevent collisions by reacting accordingly to obstacles crossing the trucks’ path. Load sensors and vision cameras further ensure accurate and safe load handling.

Side scanners for safe curves at optimum speed

Front and rear scanners for safe transportation at rated speed

Blue LED light warning pedestrians and drivers when coming out of hidden areas

Front obstacle detection for obstacles above floor level

Side obstacle detection for obstacles entering the travel path from the side

Top obstacle detection for obstacles from above

Precise navigation

Autopilot trucks from Toyota support two highly accurate and adaptive navigation technologies: reflector or natural navigation, or combined as dual navigation. The latter allows the trucks to switch between using reflectors for one area and using the warehouse environment as reference for another area of the layout.

Reflector navigation

A navigation method in which consistent and high-contrast targets, reflectors, are added to the environment. The reflectors installed in the warehouse allow the scanner on the automated truck to define its position based on its distance to the reflectors. The characteristics of this technique guarantee robustness, high accuracy and long reach in most environments.

Natural navigation

A method for automated trucks to navigate with the help of the environment. This navigation method utilises recognisable reference points or landmarks within the warehouse, such as walls, racking and fixed objects, to calculate the truck’s location. Natural navigation is a lower-cost alternative for warehouses where the surroundings remain fairly constant. The truck can utilise the existing environment to navigate without the need for extra equipment such as reflectors, avoiding extra cost and installation of additional equipment

Intelligent communication

All Autopilot trucks are controlled by T-ONE automation software designed in-house by Toyota. This software works as a standalone or as a communication layer with warehouse management and production systems. T-ONE keeps track of goods storage, orders, traffic and flow thanks to its intelligent fleet control and the integration with ERP/WMS.

Smart charging

The Autopilots can be equipped with Lithium-ion batteries that are up to 30% more energy-efficient whilst reducing CO2 emissions. With the ability of auto-charging, the trucks can charge quickly in between tasks without the need of personnel or charging rooms, making it fully automated.

Return on investment

Automation optimises the flow of goods while minimising damage, time and cost. Workers become available to handle more complex tasks instead of repetitive processes. Automated pallet handling also requires less maintenance and energy, and contributes to productivity and safety, achieving a return on investment within typically 2 years.